Ainda sem produtos na sua encomenda!

Energy efficiency has become a priority in all human activity, and reducing our ecological footprint is imperative. At the same time, Indoor Air Quality (IAQ) is increasingly valued, not only for its influence on health and well-being, but also on the productivity of those who occupy modern buildings, from homes to offices, schools, hospitals and industrial environments.

Historically, buildings had few windows and low airtightness. In single-flow CMV systems, air was only extracted, and new air entered through window gaps or passive ventilation grilles. Today, buildings are much more insulated and brighter, an evolution that requires controlled and balanced ventilation.

This is where the dual-flow CMV system with heat recovery comes in, which not only removes polluted air, but also treats it and brings the temperature of the supplied air closer to that of the return air, combining energy efficiency, thermal comfort and clean air.

Controlled Mechanical Ventilation is a system that ensures continuous and controlled renewal of indoor air.

While natural ventilation is unpredictable, CMV maintains constant air flows, improving energy efficiency and indoor air quality.

There are two main types of CMV:

Single-Flow systems work only by extracting stale air (kitchens, bathrooms, laundry rooms). Fresh air enters uncontrolled through cracks, windows, or intake grilles.

Although they are a more economical solution in the short term, they have several limitations:

The Double-Flow CMV extracts stale air and blows new, treated and filtered air into the main rooms.

Between these two flows there is a heat exchanger that transfers up to 93% of the thermal energy from the extracted air to the new air.

The result is efficient and balanced ventilation, with several advantages:

In addition, modern dual-flow units can include free cooling and free heating, using outside air to naturally cool or heat the building without additional energy consumption.

The difference between the two systems translates into significant differences in energy consumption and operating costs.

The following simulations show the monthly energy consumption and cost associated with air conditioning, considering a flow rate of 1000m³/h operating 8 hours/day and a setpoint of 20ºC, but with two different configurations:

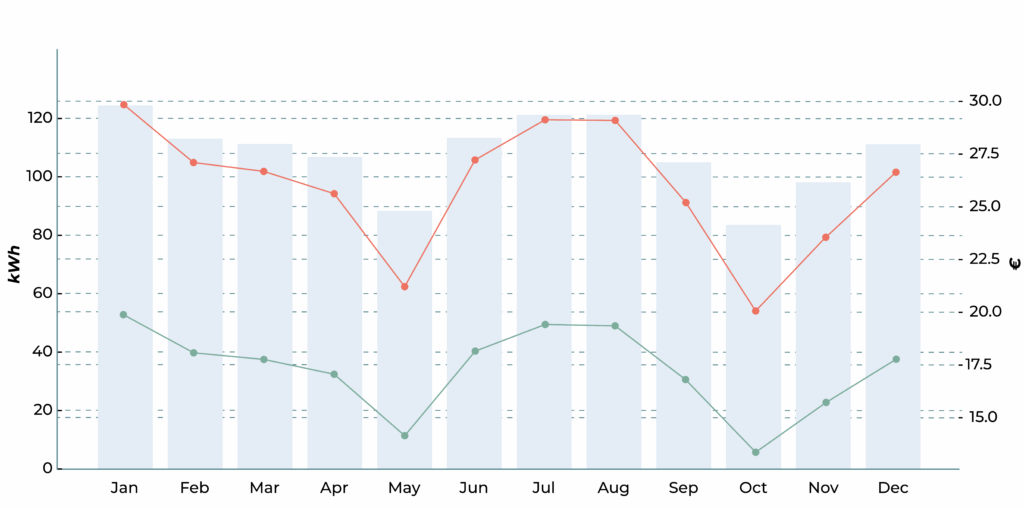

Monthly graph of energy consumption and air conditioning costs, considering a heat recovery unit with 85% efficiency and electrical heater to cover the remainder if necessary.

The bars represent total consumption (kWh) per month.

The green line indicates the energy cost at €0.16/kWh.

The red line indicates the energy cost at €0.24/kWh.

The result shows a significant reduction in energy consumption and costs during the cold months, proving the efficiency of heat recovery in heating and cooling fresh air.

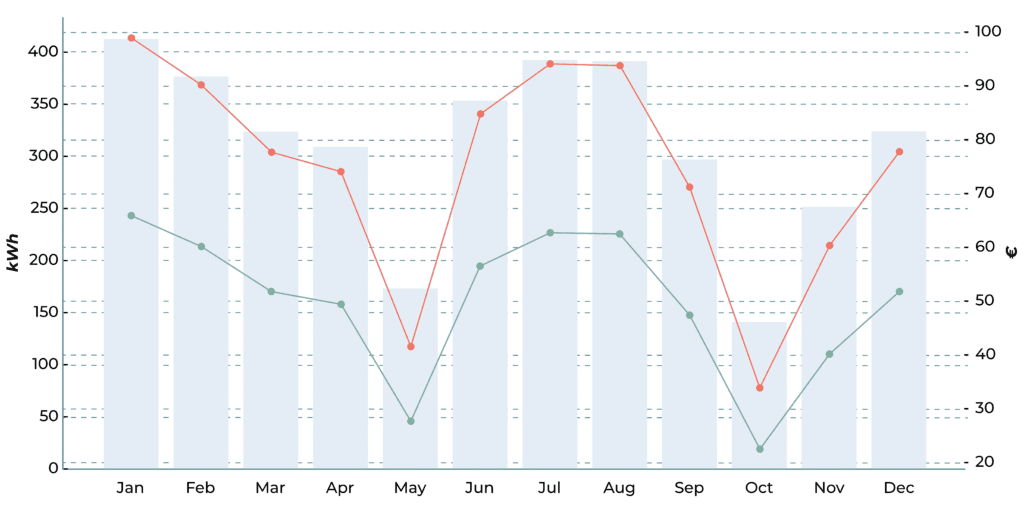

Monthly graph of air conditioning consumption and cost, considering a single-direction unit and a DX coil with outdoor unit.

The bars represent total consumption (kWh) per month.

The green line indicates the energy cost at €0.16/kWh.

The red line indicates the energy cost at €0.24/kWh.

In this scenario, energy consumption is considerably higher, especially during winter and summer, due to the absence of heat recovery; the air is heated or cooled entirely using electrical or refrigeration energy.

The difference between the two systems is significant:

These results confirm that investing in double-flow ventilation with heat recovery means investing in the efficiency, sustainability and durability of the building.

Dual-flow CMV systems are not only notable for their energy efficiency, they are also crucial for indoor air quality (IAQ) and, consequently, for the health and comfort of those who live or work in the building.

By ensuring continuous and balanced ventilation, these systems keep the air constantly refreshed, eliminating pollutants, humidity and excess carbon dioxide (CO₂). The result is a healthier, more stable and productive indoor environment.

Controlled mechanical ventilation provides:

Heat recovery ventilation is a versatile solution that can be adapted to different types of buildings, from the residential sector to industrial environments.

In all cases, the objective is the same: to ensure clean air, thermal comfort, and energy efficiency.

OCRAMclima® develops dual-flow controlled mechanical ventilation solutions with heat recovery, designed for efficiency, durability, and comfort.

The KT Home and KT Pro ranges have been designed to meet different needs, from residential spaces to buildings with higher air flow, with simple installation and optimised maintenance.

Heat recovery ventilation is one of the cornerstones of energy efficiency and indoor air quality in modern buildings.

With double-flow technology, it is possible to save energy, improve comfort and ensure a healthier and more sustainable indoor environment.

Explore OCRAMclima® solutions and discover how KT heat recovery systems can optimise energy performance and air quality.

What if there was an intelligent technological solution that connected HVAC, Lighting, Security and Safety systems? OCRAM Solutions’ BMS system provides communication between systems on a single platform, where you find the information you need to make informed decisions while improving the comfort, safety and productivity of each occupant.

BMS, Building Management System, is a tool to help maintain the various technical installations involved and integrated into the system. Process coordination, system maintenance, implementation of technical improvements and resource management are concentrated in a central hub, rather than distributed among different departments or regions of the organization.

Given the general philosophy of the building’s architectural design and the standards of reliability that are required given the nature of the building, it is recommended that the BMS should have a high degree of modularity as an indispensable feature, using a modular architecture that is compatible with the system’s expandability, is non-proprietary and has a high degree of compatibility with the integral equipment.

A Building Management System offers a number of advantages, especially for those looking to optimize their operations, guarantee uniform processes and reduce costs. The main advantages are:

To help professionals achieve their goals, our company has a highly qualified department, OCRAMSolutions, specializing in Building Manegement Systems Solutions that designs systems, from the simplest and most specific to the most complex, with high levels of programming to automate the entire complex or campus.

The systems created at OCRAMSolutions operate in compliance with the standards in force for Indoor Air Quality in buildings and for energy in the Regulation on Energy Systems for Air Conditioning in Buildings – RSECE.

The acronym IAQ refers to the assessment and control of air quality in indoor environments such as schools, universities, hospitals and other enclosed spaces. IAQ is important because the air we breathe inside these places can contain a variety of pollutants and contaminants that affect people’s health and well-being.

On average, a human being spends between 80 and 90 per cent of their time indoors, where the air contamination in these places can be up to 2 to 5 times more polluting than the air outside. The main indoor air pollutants include: volatile organic compounds (VOCs), carbon monoxide (CO), particulate matter (PM), nitrogen dioxide (NO₂), ozone (O₃), mould and fungi.

Decree-Law 101-D/2020, of 7 December, establishes requirements related to indoor air quality that must be met to guarantee a healthy environment, setting specific limits for the concentration of pollutants and other variables that affect air quality.

The decree-law applies to all buildings used for commerce and services. In addition, it specifically includes large commercial and service buildings, as well as those housing crèches, pre-school establishments, primary schools and residential facilities for the elderly.

With the expansion of access to education and the need for broader training, there has been a gradual increase in teaching hours. Portugal has the highest school workload figures in Europe, where primary school children spend around 1,000 hours a year in a classroom. In addition to the costly time spent in schools, children tend to be more vulnerable to air pollutants than adults, due to their still-developing respiratory systems.

Good IAQ is important for maintaining the health and well-being of pupils, as well as all teachers and staff, thus improving cognitive and physical development:

ParIn addition to the above, good IAQ also protects the physical structure of buildings, reduces maintenance costs, saves energy and extends the useful life of the building, generating economic benefits in both the short and long term.

At OCRAM Clima we understand the importance of healthy and comfortable indoor environments. Teaching centres are no exception; on the contrary, they are extremely important. With our experience and expertise in air quality, we offer customised solutions designed to meet specific needs.

OCRAM Clima’s commitment is to guarantee a healthy environment that promotes learning and well-being, while minimising health risks for students, teachers and staff alike.

We know how to revolutionize buildings, but for the better. With the modernization of HVAC systems and all the associated benefits, OCRAMclima is the national brand that stands out for combining high-quality materials and innovative solutions, seeking to lead the market and offer sustainable solutions for customers and all buildings.

Retrofit method not only improves the performance of existing systems, but also reduces energy consumption and operating costs. Retrofitting not only improves the performance of existing systems, but also reduces energy consumption and operating costs. OCRAMClima is at the forefront of this process, offering customized solutions that transform old systems into models of efficiency and sustainability. In this article, we explore the concept of retrofitting, its benefits and how OCRAMClima can help your company achieve these goals.

Retrofit is the process of updating and improving existing climate control systems so that they work more efficiently and with less environmental impact. This can include replacing obsolete components, incorporating new technologies and optimizing systems for better performance. Unlike a simple replacement of equipment, retrofitting involves an integrated approach that considers the interaction between all the components of the system and the environment in which they are installed.

The percentage of savings varies depending on several factors, including the type of components replaced, the efficiency of the new components and the general state of the existing system. According to some research and sources we consulted, in general terms:

OCRAMClima takes a comprehensive and personalized approach to each retrofit project, ensuring that HVAC systems are upgraded according to the specific needs of each client and each building The process includes several key stages, from diagnosis to project development and implementation.

An initial analysis of the existing systems is carried out, where opportunities for improvement are identified and exploited in the project development phase. The implementation phase is equally important to ensure that the changes are implemented as planned.

OCRAMClima has already helped a number of companies and buildings modernize their systems through retrofitting. Clients report significant changes in performance and consumption!

Retrofitting is a smart and sustainable solution for companies looking to improve energy efficiency, reduce costs and promote a healthier and more comfortable environment. OCRAMClima stands out in this market, offering retrofit solutions that transform old systems into models of efficiency and sustainability.

If you want to modernize your system, OCRAMClima is the ideal partner to achieve these goals, talk to us!

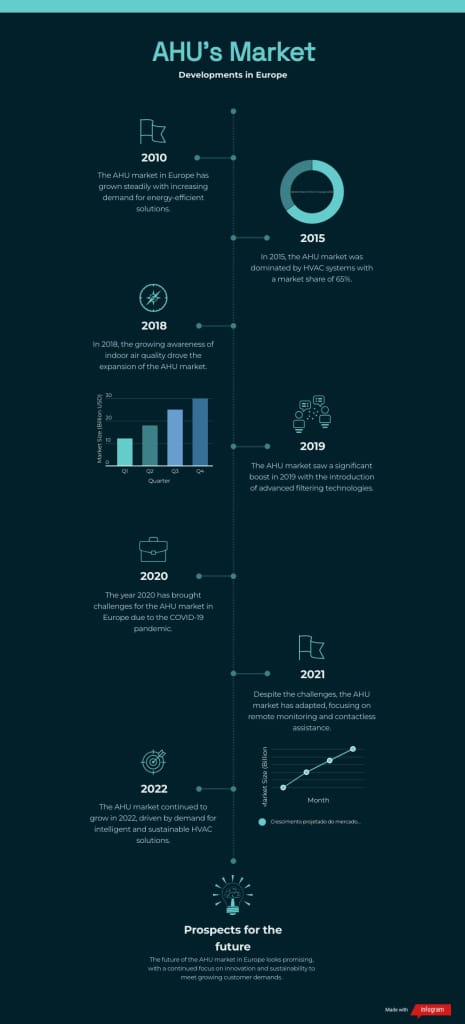

Between 2018 and 2022, the compound annual growth rate (CAGR) was between 4% and 5%, and the market was valued at 50 million euros in 2022, driven by the modernization of infrastructures and the adoption of new technologies.

By 2028 the growth rate is expected to be approximately between 5% and 6%, reflecting the importance of Indoor Air Quality and Energy Efficiency.

AHUs are equipment used in heating, ventilation and air conditioning (HVAC) systems to condition and circulate air in an enclosed space. The main function of an AHU is to guarantee indoor air quality, providing thermal comfort and health to the occupants of a building. AHUs are essential components in commercial, industrial and residential buildings.

Technological advances allow Air Handling Units to be designed to have lower energy consumption, use advanced sensors to optimize their performance and are therefore more energy efficient. They can integrate control systems based on IoT (Internet of Things) and automation that enable monitoring, remote management and predictive maintenance.

All AHU manufacturers are under pressure to develop products that are more sustainable and ecologically acceptable to the market, due to environmental standards and stricter regulations regarding carbon emissions.

The combination of several factors drives the Air Handling Units sector and market, making this area a booming one and a focus for innovation. This interconnection allows various focuses such as well-being, sustainability, energy efficiency, among others, to be addressed and allows the sector to gain popularity.

The Air Handling Units (AHUs) market is gaining popularity due to growing concern about indoor air quality and its impact on health and well-being. With the COVID-19 pandemic, awareness of the importance of healthy indoor environments has increased significantly. Effective AHUs help to remove contaminants, allergens and pathogens from the air, creating safer and more comfortable spaces. In addition, advanced air filtration and purification technology has become more accessible, allowing more buildings to improve air quality.

The integration of automation and Internet of Things (IoT) systems enables remote monitoring and control, performance optimization and predictive maintenance. High-efficiency filters, such as HEPA and UV disinfection technologies, are raising air quality standards, attracting greater interest and adoption of these units in various sectors, including commercial, industrial and residential.

On the other hand, with a close eye on sustainability and energy efficiency, they are driving growth in this sector. With increasingly strict environmental regulations and a global focus on reducing the carbon footprint, modern AHUs are designed to maximize energy efficiency. Heat recovery systems and automation technologies are being incorporated to reduce energy consumption and operating costs, making AHUs a popular choice in sustainable buildings.

AHUs are essential for maintaining ideal temperatures, adequate humidity levels and high air quality, which improves occupant comfort and productivity. In addition, well-conditioned environments reduce absenteeism related to health problems such as allergies and respiratory diseases, making these units indispensable in offices, schools and hospitals.

The Air Handling Unit (AHU) sector is on the rise due to the growth of the green building sector and the search for environmental certifications such as LEED. Sustainable buildings require efficient air treatment systems that help save energy and reduce the carbon footprint. AHUs incorporating high-efficiency heat recovery and filtration technologies are becoming standard in new construction projects, driving popularity and continued innovation in this sector.

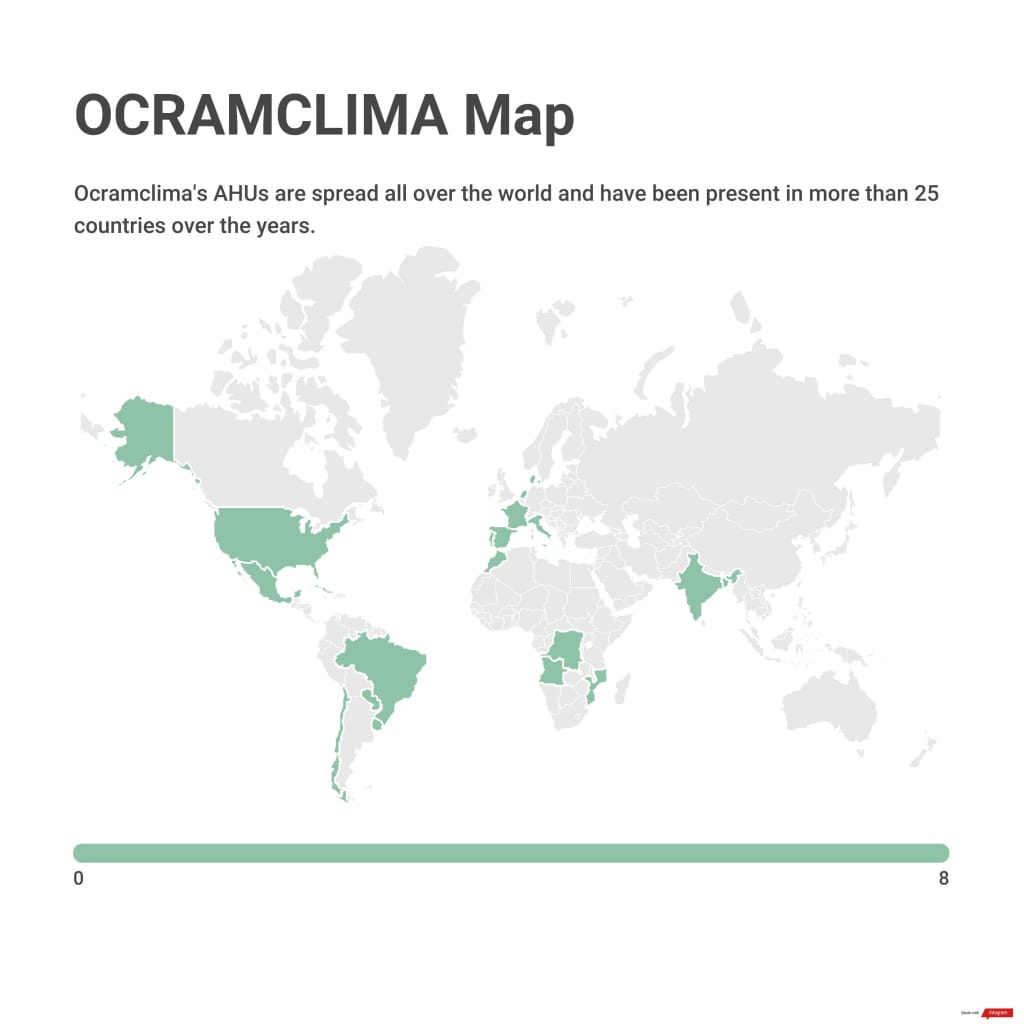

Ocramclima, a national brand with local manufacturing, is well positioned in the air handling unit (AHU) expansion scenario due to several competitive advantages. The brand, known for its innovations and customized solutions, is in line with the main trends driving the AHU market.

Focus on Indoor Air Quality (IAQ): Ocramclima offers solutions to improve indoor air quality, which is crucial for health and well-being, especially in times of increased awareness about the importance of clean air.

Sustainability and Energy Efficiency: Ocramclima develops AHUs that are highly energy efficient, helping to reduce the carbon footprint of buildings. Its units incorporate heat recovery technologies and are designed to maximize energy efficiency while complying with environmental regulations.

Technological Innovation: Ocramclima develops AHUs that are highly energy efficient, helping to reduce the carbon footprint of buildings. This not only improves operational efficiency, but also reduces maintenance costs and increases the durability of the systems.

Comfort and Productivity: Ocramclima’s solutions are designed to provide comfortable indoor environments, maintaining optimum temperatures and humidity levels. This is essential for the productivity and well-being of occupants, an important factor for customers in commercial, industrial and healthcare sectors.

Support for Green Construction: Ocramclima supports sustainable construction by providing AHUs that contribute to environmental certifications such as LEED. Solutions are sought in new construction projects that aim to be environmentally friendly and energy efficient.

With a portfolio covering advanced air handling unit solutions, Ocramclima is well placed to take advantage of market growth. The brand’s focus is on quality, innovation and sustainability, which makes it a preferred choice in a rapidly evolving sector, ensuring that it remains competitive and relevant in the global HVAC market.

This May, we were recognised with the new TÜV hygienic certificate, and we are the first company in the world to receive it. Ocram Clima continues to lead the way in improving air quality in hospital environments, standing out for its commitment to innovation, quality and safety, as evidenced by the award of the new hygienic certificate, which you can see here. The renewal of the hygienic certificate, formerly attributed by the ILH BERLIN organisation, sets the pace for continued dedication and commitment to finding new and better solutions.

In this context, Ocram Clima has established itself as a company dedicated to ensuring that air quality in hospital environments is optimised to promote the health and comfort of patients and healthcare professionals. In this article, we’ll explore the contours of hospital buildings, the importance of air quality and the differences between Air Handling Units (AHUs) and Hygienic Air Handling Units (HAHUs), highlighting how Ocram Clima plays a crucial role in this scenario.

Hospital architecture goes far beyond aesthetics and functionality; it plays a vital role in the effectiveness of healthcare, directly influencing the well-being of patients and the operational efficiency of professionals. The contours of hospital buildings must be carefully planned to ensure not only accessibility and safety, but also to promote air circulation and the maintenance of a healthy environment.

Ocram Clima understands the importance of these contours and dedicates its work and research to finding solutions that meet the specific needs of each hospital space. Whether in operating theatres, intensive care units or waiting areas, good air quality must be guaranteed, minimising the risk of cross-contamination and providing optimal conditions for patient recovery.

Air quality in hospital environments is a concern because of the potential impact on the health of patients, visitors and healthcare professionals. Whether in an operating theatre, sterile area or recovery room, the presence of pathogens, allergens, harmful particles and air pollutants can aggravate existing medical conditions and even trigger new health problems.

Advanced air purification, filtration and humidity control technologies are required to maintain air quality standards in line with standards. In addition, our company offers customised monitoring and maintenance solutions to ensure that systems are always operational at maximum efficiency, thus minimising the risks of contamination and providing a safe and healthy environment for all occupants.

What are the differences between air handling units (AHU) and hygienic air handling units (HAHU)? Although they share the goal of providing clean, controlled air, there are significant differences in their construction and the functions they perform.

Conventional AHUs are designed primarily for thermal comfort and air circulation in commercial, industrial and private environments, among others… On the other hand, AHUs are specifically designed for sensitive environments such as hospitals and laboratories, where air quality is of the utmost importance.

Ocram Clima’s UTAH differs in its air registers, filter sections, finishes and surfaces, among other characteristics that make it suitable for sterile environments. These machines are Eurovent-certified and comply with the KKL/1023/21 hygienic regulations (TÜV NORD Systems certification).

The previous ILH BERLIN certificate has now been upgraded to TÜV NORD Systems. The TÜV brand is recognised globally and is based on safety, reliability and neutrality. It has an excellent reputation globally among customers and business partners and is committed to delivering ‘Excellence for Your Business’.

Hospital “Vila Verde”

The Portuguese Institute of Oncology of Lisbon Francisco Gentil E.P.E. (IPO Lisboa)

Bial

Hospital “Senhor Bonfim”

Hospital “Santa Luzia Viana Castelo”

Paediatric Emergency “Évora”

Clinics Fresenius

Hospital Center Porto

São João Hospital and University Centre

“Trofa Saúde”

Hospital of “Lousada”

Hospital of “Senhora da Oliveira (Guimarães)”

Hospital Center “Douro e Vouga”

Guarda Local Health Unit

D’Aufrery Clinic

Montpellier Onchology

Hospital “Privé du Bois”

Hospital “Joseph Ducuing”

Octapharma

Herlev Hospital

Pharmaceutical Industry

Hospital Privé Pasteur

Clinics

Sérum Institute

Pharmaceutical Industry

Hospital units

Photo credits: “Instituto Superior Técnico”, University of Lisbon

Lisbon’s Technical Innovation Centre, a hub of innovation and excellence, is becoming a landmark not only for its historic architecture, but also for its advanced vision in technology and sustainability. At the heart of this visionary project are the OCRAM Clima Air Handling Units (AHUs) installed by HVAC specialist – Globaltérmica, Instalações Mecânicas, SA

From a former railway station to a state-of-the-art space, this centre is an ideal meeting point for scientists, students and entrepreneurs, where they have tried to keep some materials intact by combining them with new and efficient ones.

In large-scale buildings such as the Lisbon Technical Innovation Centre, which offers a 24-hour study area, an exhibition space, cafeteria and restaurant, auditoriums and an advanced first aid area, AHUs play a crucial role in maintaining a comfortable and healthy internal environment. They are responsible for regulating the temperature, humidity and quality of the air, guaranteeing ideal conditions for the well-being and productivity of the occupants.

The AHUs supplied for this project are equipped with state-of-the-art technology to minimise energy consumption and reduce environmental impact, but also contribute to reducing operating costs in the long term.

From design to installation and ongoing maintenance, OCRAM Clima and Globaltérmica are committed to providing exceptional support and ensuring the optimal performance of AHUs over time.

This project exemplifies the transformative potential of collaboration between companies committed to excellence, innovation and sustainability. By joining forces, OCRAM Clima and Globaltérmica have not only contributed to the creation of a high-quality indoor environment at the Lisbon Technical Innovation Centre, but have also set a high standard for future projects around the world.

Read the Euronews story here: https://www.euronews.com/my-europe/2024/04/01/discover-lisbons-historic-tecnico-innovation-centre?twclid=2-s0xpjdjszkt5ztdhc6ggz1v0

It is with great pride and joy that in November 2023 we celebrated a significant milestone in our business journey: the 25th anniversary of Vieira & Lopes. Throughout this quarter of a century, our company has been a driving force for innovation, commitment and excellence in our sector.

This journey began with a dream and a vision of the future, which has been transformed, always with many changes, challenges and triumphs, but maintaining values of integrity, quality and customer service.

In the video we are sharing today, we invite you to take a look back at this moment of joy, sharing and celebration that brought our entire team together.

On this milestone, we would like to take this opportunity to express our deep gratitude to all those who have contributed to Vieira & Lopes’ success over the years – our clients, partners and, above all, our dedicated employees, whose commitment and talent are the soul of the company.

While we praise in the memories of the past, we also look forward with enthusiasm to the future. The next 25 years promise new challenges, exciting opportunities and even greater achievements. Based on our heritage of integrity, innovation and excellence, we are ready to face what the future holds and continue to write Vieira & Lopes’ success story.

Thank you for joining us on this journey. Together, we celebrate 25 years of achievements and eagerly anticipate those to come.

Vieira & Lopes: 25 years of excellence, 25 years of commitment, 25 years of success!

Ocram Clima, a leading company in the development and manufacture of advanced climate control solutions, is proud to announce the production of equipment for the Extremely Large Telescope (ELT) mega observatory project, located in the Atacama Desert in Chile.

Photo credits: ESO – European Southern Observatory

The project, led by the European Southern Observatory (ESO), is valued at 1.45 billion euros and will include 46 Air Handling Units (AHUs). As a whole, the Air Treatment Units, to be installed by mid-2024, will have the task of guaranteeing thermal stability inside the ELT and providing the ideal conditions for the telescope’s operations, whose first scientific observations are expected in 2028.

The cooling capacity during hours of sun exposure is orchestrated with other unique aspects of the building, such as the thermal insulation of the floor between the pillars and the dome to prevent pockets of hot air; the aluminium coating on the dome shell that reinforces the insulation for a stable temperature or the special seals that prevent air exchange and dust from entering the enclosure.

A modern engineering milestone the size of the ELT includes an ambitious ventilation project – designed to operate efficiently in the face of major thermal variations and to protect the telescope from the elements, typical of the latitude where the structure is being built.

Environmental control inside the ELT requires control of the surrounding air to eliminate any disturbance to visibility in the optics area and prevent thermal deformation of the telescope structure. The ventilation system will provide a smooth transition between the inside temperature of the dome and the expected outside temperature, keeping it stable during night-time observations after the doors open – which occurs shortly after sunset.

“With the construction of AHUs for the ELT, Ocram Clima is once again committed to excellence in creating indoor environments where air quality, precision and thermal stability are a reality. Our long list of important references in different parts of the world is now joined by our contribution to the world’s largest telescope: crucial for probing the far reaches of the cosmos and opening up new possibilities for all of humanity. A commitment that fills us with pride,” says Marco Lopes, CEO of Vieira & Lopes, Lda, which owns the Ocram Clima brand.

Work on the ELT project, approved in 2012, was given the green light to start in 2014. The result of an international collaboration involving dozens of European companies, the optical/infrared telescope, the world’s largest eye open to the exploration of the universe, will be ready to offer unprecedented views of celestial bodies from the delicate optical structure that makes up the telescope. Integrated into a dome 80 metres high and with a diameter of 88 metres, which occupies a ground area equivalent to a football field, the upper body of the structure will rotate to allow the telescope to point in any direction from its observation slit, with minimal vibration and great precision.

Although the widespread enthusiasm is due to the vast possibilities that the ELT offers in the exploration of the cosmos – from the search for Earth-like planets to the detection of extrasolar life – the telescope in Chile is already the realisation of many scientific advances. The diversity of instruments using cutting-edge technology with the potential to revolutionise our understanding of the Universe is paralleled only by the impact of Galileo’s telescope four centuries ago.

Honoured to see its products equipping the world’s largest telescope, Ocram Clima celebrates this technological achievement as an important milestone in the development and manufacture of advanced climate control systems, renewing its commitment to innovation. The company plays a key role in creating controlled and precise environments for the most diverse applications, including other cutting-edge projects such as ELT.

Featured image credits: Dorte Mandrup Arkitekter

An architecturally open project, set in a splendid location that truly justifies the expectation. Quite distinct from the classic blue warehouse of IKEA, the newly inaugurated store is a product of the creative flow of Dorte Mandrup, named Monocle’s Architect of the Year in 2022 for her finesse and fluidity in seamlessly integrating each building into the surrounding landscape.

Accessible by train or bicycle, the new IKEA in Vesterbro is, as promised since the project kicked off in 2015, light and green. The building, located with direct access to Dybbølsbro Bridge, is now part of Copenhagen’s coolest district.

The public access terrace also serves as a pedestrian pathway and a tribute to biodiversity. A curtain-inspired facade gives a sneak peek into a spacious living room with big glass panels, white surfaces, and plenty of green plants.

“We described many of the building’s specific features in the article we published here where we announced Ocram Clima’s contribution to the project. We supplied 12 custom-designed Air Handling Units to match the project’s ambitions. “Efficiency is the guiding principle in these units, tasked with delivering between 10,000m³ and 36,000m³ of treated air every passing hour within the new IKEA space.” Achieving Eurovent-certified performance, with minimal energy consumption, to ensure a comfortable temperature and fresh air for extended visits to IKEA.

Ocram responded to the ventilation for the entire building, encompassing a parking basement, a three-story warehouse, rooftop garden, utility facilities, and personnel building.

The name IKEA conjures a set of instantly recognizable signals: the modular formula that defines most of its products, many of which have become symbols of our urban culture; the product design, consistently extended to packaging and the practical assembly aspect; or the iconic yellow logo on a blue background and the structure of stores – vast spaces we navigate with familiarity, whether we’re in Scandinavia, a sunny Southern European country, or the chilly province of Saskatchewan.

Amidst the bustling city of Copenhagen, in the Vesterbro district, an IKEA store is emerging as the epitome of change: both for IKEA itself and the concept we hold of it. Guided by the mission to reshape the building’s rapport with the community, while also envisioning design with a strong commitment to the environment and sustainability.

The growing occurrence of these phenomena underscores the importance of reassessing our energy choices in response to the climate crisis. Constructing buildings entails giving new functions and meanings to spaces. The project of architect Dorte Mandrup’s eponymous studio for the new IKEA store mirrors this process, founded on the daily management of energy, sustainability, and the surrounding community— the cornerstone principles of the entire project. Aspires to earn the world’s most stringent sustainability assessment label, the BREEAM Certification.

An endeavour emphasized by the 1450m2 of solar panels and the use of water from local canals to cool the shop. Ocram’s Air Handling Units have been meticulously designed with energy-saving systems and heat recovery technologies, employing various methods for enhanced operational efficiency.

The home goods retailer encourages urban visitors to adopt sustainable transportation methods, featuring a spacious section dedicated to bicycle parking and offering cargo bikes for customers who wish to transport their furniture home while burning some calories.

The new store aims to support Copenhagen’s endeavors as it strives to become the world’s first carbon-neutral city by 2025. In alignment with the city’s eco-conscious outlook, IKEA is also taking a substantial stride towards achieving its goal of becoming a circular business by 2030.

This isn’t the first time OCRAM has manufactured equipment for IKEA store ventilation systems. However, the building set to open in the summer of 2023 stands out from all the others. The Air Handling Units have been meticulously designed to fully align with the goals of the new project. 12 AHUs will deliver purified air flows throughout the space, ranging from 10.000m3/h to 36.000m3/h. Our Air Handling Units are EUROVENT-certified for performance, equipped with efficient heat recovery systems that guarantee low energy consumption and a comfortable in-store temperature.

The store’s exterior is also a reflection of its harmonious blend with nature. The rooftop transformed into a park creates a city oasis with hundreds of trees, native species, shrubs, and insect shelters that support biodiversity. Sheltered areas from the wind and sun beckon spontaneous gatherings. Small green havens stretch over 150 meters of landscape design. This is a genuine oasis positioned 20 meters above the bustle of the streets and the close railway station, offering itself to a densely populated area of the city, lacking in green spaces.

But the entire building challenges the classic complement of accompanying the blue and yellow elements of IKEA. Here, the facade adorns itself with shades of green as it draws inspiration from the organic flow of a billowing white curtain. Hanging from the edges of the roof, these are slightly parted in selected sections to reveal the exhibition spaces within the store.